Galden® HT PFPE Heat Transfer Fluids

Galden® HT PFPEs can be employed as Heat Transfer (HT) media for demanding conditions in a variety of fields and applications:

• Semiconductor

• Chemical

• Pharmaceutical

• Vapor phase heating

• Transformer and supercomputer cooling

• Recirculating chillers

• Nuclear

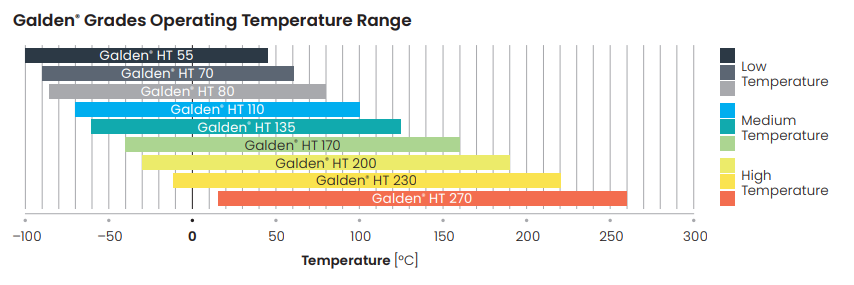

Galden® HT PFPEs are inert, dielectric and high-performance heat transfer fluids with boiling points ranging 55°C to 270°C.

This range is unique among the fluorinated fluids on the market and enables Galden® HT PFPEs to be employed at end-use temperatures ranging below -100°C up to 290°C.

.png)

Features and Benefits of Galden® HT PFPE

|

Features |

Benefits |

|

Excellent thermal and chemical stability |

No corrosion or reaction with construction materials |

|

Good compatibility with materials |

No formation of decomposition residues No circulating pump seizure due to fluid degradation or corrosion |

|

Good heat transfer performance |

Good temperature control |

|

Grades with a wide range of boiling point |

Wide choice of grades to optimize performance |

|

High boiling point with low pour point and low viscosity |

High boiling grades reduce evaporation losses without affecting performance |

|

Low evaporation losses |

Low costs of ownership |

|

No flash point No fire point No explosion hazards No auto-ignition point FM Approval 6930 |

Safe to use at high temperature No fire hazard Lower fire prevention costs |

Galden® End-Use Temperature Segmentation

The broad selection of average molecular weights enables the use of Galden® Heat Transfer Fluids across the range of typical temperature requirements.

Low Temperature

Galden® HT 55, HT 70 and HT 80 are ideally suited for applications requiring transferring heat at temperatures well below the water freezing point. These products enable thermal management in conditions far below what can be achieved by other products while maintaining the unique non-flammability characteristics that distinguish fluorinated fluids.

Medium Temperature

Galden® HT 110, H 135 and HT 170 perfectly cover the applications requiring a balance of low evaporative losses and leak control while maintaining good thermal transfer capabilities even at temperatures below 0°C. These fluids can also be used at moderate temperatures to replace fluids with higher evaporation rates while preserving heat transfer performance.

High Temperature

A line of dielectric fluids with boiling points above 200°C, these high-performance fluids are engineered for high-temperature applications. Thanks to their high boiling point, they offer a significantly lower evaporation rate and can work in demanding conditions up to 260°C without requiring over-pressurized systems.

Technical data sheet of Galden® HT PFPEs

|

Low Temperature |

Medium Temperature |

High Temperature |

||||||||

|

Properties |

Units |

HT55 |

HT70 |

HT80 |

HT110 |

HT135 |

HT170 |

HT200 |

HT230 |

HT270 |

|

Boiling point |

°C |

55 |

70 |

80 |

110 |

135 |

170 |

200 |

230 |

270 |

|

Pour point |

°C |

<–125 |

<–110 |

–110 |

–100 |

–100 |

–97 |

–85 |

–77 |

–66 |

|

Density |

g/cm3 |

1.65 |

1.68 |

1.69 |

1.71 |

1.72 |

1.77 |

1.79 |

1.82 |

1.85 |

|

Kinematic viscosity |

cSt |

0.45 |

0.50 |

0.57 |

0.77 |

1.00 |

1.80 |

2.40 |

4.40 |

14.00 |

|

Vapor pressure |

torr |

225 |

141 |

105 |

17 |

5.8 |

0.8 |

0.2 |

0.03 |

<10–2 |

|

Specific heat |

cal/g •°C |

0.23 |

0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 |

|

Heat of vaporization at boiling point |

cal/g |

22 |

17 |

17 |

17 |

16 |

16 |

15 |

15 |

15 |

|

Refractive index |

– |

1.280 |

1.280 |

1.280 |

1.280 |

1.280 |

1.280 |

1.281 |

1.283 |

1.283 |

|

Coefficient of thermal expansion |

cm3/cm3 •°C |

0.0011 |

0.0011 |

0.0011 |

0.0011 |

0.0011 |

0.0011 |

0.0011 |

0.0011 |

0.0011 |

|

Surface tension |

dyne/cm |

14 |

14 |

16 |

16 |

17 |

18 |

19 |

19 |

20 |

|

Thermal conductivity |

W/m•K |

0.067 |

0.067 |

0.067 |

0.067 |

0.067 |

0.065 |

0.065 |

0.065 |

0.065 |

|

Dielectric strength |

kV (2.54mm gap) |

40 |

40 |

40 |

40 |

40 |

40 |

40 |

40 |

40 |

|

Dielectric constant |

– |

1.86 |

1.86 |

1.89 |

1.92 |

1.92 |

1.94 |

1.94 |

1.94 |

1.94 |

|

Volume resistivity |

Ohm•cm |

1 •1014 |

1 •1015 |

1.5•1015 |

1.5•1015 |

1.5•1015 |

1.5•1015 |

6•1015 |

6•1015 |

6•1015 |

|

Average molecular weight |

amu |

340 |

410 |

430 |

580 |

610 |

760 |

870 |

1,020 |

1,550 |

Safety and Low-Maintenance

The chemical inertness of Galden® HT PFPE fluids makes them ideal candidates for all the most demanding applications. Their non-corrosivity and intrinsic stability minimize the need for fluid changes and maintenance actions, maximizing the uptime of equipment and reducing operating costs.

Galden® HT PFPE fluids have Zero Ozone Depletion Potential (ODP), nevertheless their use is encouraged in fully-sealed systems to minimize loss to the environment and reduce any environmental impact that may be connected with it.

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon