What is solder wire?

Soldering, often confused with welding, is a well-established technique used to join metal components. This process involves heating a metal-typically with a flame or another high-temperature source-until it reaches its melting point and becomes liquid. Once molten, the metal can be used to fuse two surfaces without the use of adhesives, as the intense heat enables the materials to bond at a molecular level. For the joint to be strong and reliable, it’s crucial that the metals involved are chemically compatible, especially when working in environments where oxygen is present, as it may lead to unwanted oxidation or other adverse reactions.

Among the various materials used in soldering, solder wire plays a particularly vital role. It is one of the most commonly used tools in the process, valued for its ability to form secure, long-lasting joints that meet demanding technical standards. Solder wire ensures both mechanical strength and electrical conductivity in the final connection. This article will explore the advantages of using solder wire, the different types available on the market, and how to select the most appropriate type for your specific application needs.

Exploring the various types of Solder Wire

Leaded solder wire

Leaded solder wire is primarily made from a tin-lead alloy, most commonly in a 60/40 ratio-comprising 60% tin and 40% lead. This formulation provides a relatively low melting point, typically ranging from 183°C to 190°C (361°F to 374°F), which enables efficient heat transfer and faster soldering. The inclusion of lead enhances the solder’s wettability, making it easier for the molten material to spread evenly across metal surfaces. This results in smooth, glossy solder joints that are both reliable and visually clean. Due to its softness, leaded solder wire is ideal for low-stress applications where mechanical strength is not a critical factor.

Nevertheless, increasing awareness of the health hazards and environmental impact of lead has led to widespread restrictions on its use. Regulatory bodies-most notably the European Union’s Restriction of Hazardous Substances (RoHS) Directive-have prohibited the use of leaded solder in many consumer electronics and related industries. In response, manufacturers such as Sonic Solder Wire, Inc. are actively shifting toward lead-free solder alternatives to meet global regulations and support sustainability initiatives.

Lead-free solder wire

The use of lead-free solder wire has seen a substantial rise, largely driven by environmental regulations and a growing global commitment to safer, more sustainable manufacturing practices. One of the main ecological advantages of lead-free solder is its potential to minimize health and environmental hazards traditionally linked to lead-based materials. Thanks to advancements in alloy technology, modern lead-free solders now offer enhanced mechanical properties, including greater hardness and durability, which contribute to strong, reliable solder joints.

That said, lead-free solder does come with certain challenges. It typically requires higher soldering temperatures, which can result in increased energy consumption and a higher risk of thermal damage to delicate components. Furthermore, lead-free solder tends to be more brittle than its leaded counterpart, making it prone to cracking, especially in thin layers exposed to thermal cycling or mechanical stress.

Despite these drawbacks, the outlook for lead-free solder remains positive. Continuous innovation is helping to overcome current limitations, improving overall performance and expanding its suitability across a wide range of industries.

Specialty solder wires: Silver, Flux-Core and other variants

Certain solder wire variants are specifically engineered for specialized applications, addressing the unique requirements of various industries. For example, silver solder wire is commonly employed in high-performance electronics, aerospace systems, and other precision technologies due to its exceptional electrical and thermal conductivity. Its higher melting point compared to standard solder makes it particularly suitable for environments exposed to frequent temperature fluctuations, where robust and stable connections are critical.

Another notable type is flux-core solder wire, which contains a central core of flux material. This built-in flux streamlines the soldering process by removing the need for separate flux application, significantly improving efficiency. Flux-core solder is especially useful in field repairs and automated high-speed production lines, where speed, consistency, and reliability are vital. Its formulation enhances wetting behavior, leading to stronger, more consistent solder joints.

Moreover, some specialized solder wires are developed with low-melting-point alloys or are formulated to provide superior mechanical strength and resistance to corrosion. These wires are meticulously produced to meet strict performance standards, ensuring that the resulting connections are durable, high-quality, and capable of withstanding challenging operational environments.

Key benefits of using Solder Wire

-

Solder wire provides a range of significant advantages over other soldering methods, making it a preferred solution across numerous applications:

-

Highly effective for small-scale or limited production batches, offering precision and control without the need for extensive equipment.

-

Ideal for working with delicate or miniature components, thanks to its ability to deliver targeted heat with minimal risk of damage.

-

Well-suited for prototype development and testing, allowing for quick adjustments and reliable connectivity during the design phase.

-

Practical and convenient for repair and maintenance work, especially in field conditions or situations requiring manual precision.

-

Offers excellent durability, with strong resistance to wear, fatigue, and environmental degradation over time.

-

Demonstrates superior wetting properties, which enhance the flow of solder and reduce oxidation during the process, ensuring cleaner, stronger joints.

How to use Solder Wire effectively: a step-by-step guide

1. How to connect wires with crimp terminals

Use a pair of wire strippers to carefully remove approximately one centimeter of insulation from the end of the wire. Once exposed, twist the wire strands tightly with your fingers to prevent them from fraying or separating.

.png)

Align the color-coded section of your crimping tool with the color of the crimp terminal you’re using. Insert the stripped end of the wire into the terminal so that the bare wire is fully covered-ensuring no exposed strands remain outside-while making sure it reaches far enough to make proper contact within the crimping area.

Firmly squeeze the crimping tool to securely compress the terminal around the wire, ensuring a tight and reliable connection.

Gently pull on the wire to confirm that it is securely fastened and properly crimped in place.

2. How to solder wires together with a soldering Iron

When joining two wires, begin by stripping about one to two centimeters of insulation from the ends of both wires to expose the conductive core.

Slide a 3-centimeter section of heat shrink tubing onto one of the wires, making sure to position it at least 10 centimeters away from the area where the wires will be joined.

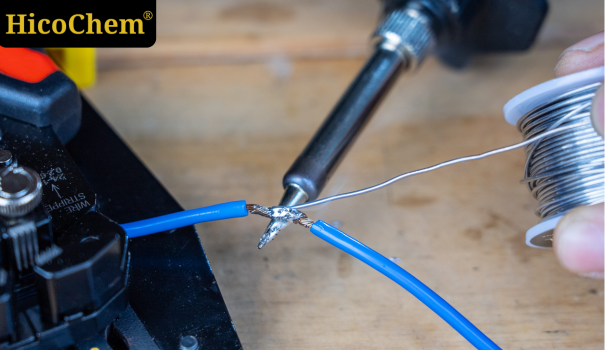

Position the stripped wire ends in a cross formation and twist them tightly together to create a secure mechanical connection.

If you're splicing into an existing wire, use wire strippers to remove a small section of insulation from the original wire, then wrap the stripped end of the new wire securely around the exposed section.

Let the soldering iron heat up for a few minutes. You’ll know it’s ready when touching it with a bit of solder produces a small puff of smoke.

Next, apply a small amount of solder to the iron’s tip—a process known as “tinning”—to improve heat transfer and ensure smooth solder flow.

3. How to make strong wire connections with Soldering

Press the tinned tip of your soldering iron against the twisted wire joint and hold it there for a few seconds to allow the area to heat evenly.

Carefully feed additional solder into the joint, positioning it exactly where the iron touches the wires.

The solder should begin to flow smoothly through the joint, creating a solid bond.

If the solder fails to melt or simply pools on the surface, continue applying heat for a few more seconds, then try again.

Once the solder has cooled and solidified, slide the heat shrink tubing over the joint, and use a heat gun or blow torch to shrink it securely in place, providing insulation and protection.

In cases where you’ve made a splice into an existing wire and can’t use heat shrink, wrap the joint securely with high-quality electrical tape to ensure proper insulation and durability.

How to select the most suitable Solder Wire

Choosing the most suitable solder wire for your project requires a careful evaluation of several technical factors to ensure optimal performance, reliability, and cost-effectiveness. Below are the key aspects to consider:

-

Melting Point: The solder wire’s melting temperature should be compatible with the thermal limits of the components being joined. For high-temperature applications—such as those in aerospace—silver-based solder is often the preferred choice. With a melting range of approximately 700°F to 800°F, it provides strong, heat-resistant bonds capable of withstanding thermal stress.

-

Electrical Conductivity: In high-density electronic systems, maintaining strong electrical performance is essential. Solder wires alloyed with silver or gold are ideal for such applications due to their exceptional conductivity, helping to reduce signal loss and improve overall device efficiency.

-

Tensile Strength: Solder joints must be mechanically stable to resist vibrations, physical loads, and long-term stress. Alloys containing copper or nickel offer superior tensile strength, resulting in durable connections that withstand wear and fatigue over time.

-

Flux Type: The integrated flux core within solder wire plays a crucial role in the quality of the bond. No-clean, low-residue flux is best suited for applications where post-solder cleaning is not feasible. Conversely, heavily oxidized surfaces may require high-activity flux to ensure proper wetting and adhesion.

-

Corrosion Resistance: In environments prone to moisture, chemicals, or extreme conditions, corrosion resistance is vital. Solder wires formulated with tin, zinc, or other protective elements enhance resistance to environmental degradation, thereby prolonging joint life and reliability.

-

Cost Efficiency: While advanced solder alloys deliver high performance in demanding scenarios, budget considerations remain important. Striking the right balance between technical performance and cost helps ensure the selection of a solder wire that meets project needs without overspending.

Avoid these common errors when selecting Solder Wire

Choosing the right solder wire for electronic applications requires thoughtful evaluation to prevent issues that could impact functionality and reliability. One of the most important considerations is the alloy composition and melting temperature. Overlooking these properties can lead to weak or unstable solder joints and may even harm delicate components if the heat applied is excessive.

Equally crucial is the selection of an appropriate flux. Using the wrong type can cause poor wetting behavior, resulting in fragile or intermittent electrical connections. The flux must be compatible with both the base materials and the specific conditions of the soldering process.

Another frequent mistake is neglecting compliance with environmental standards, such as the RoHS (Restriction of Hazardous Substances) directive. Employing solder wire with high lead content in jurisdictions where such substances are restricted can render the product non-compliant and unfit for distribution.

To ensure optimal results, it’s important to align your solder wire choice with the technical demands of the application, material compatibility, and regulatory frameworks. A well-informed decision not only guarantees dependable performance but also upholds safety and legal standards in manufacturing.

Common applications of Solder Wire

Solder wire plays a vital role across numerous industries, with its most prominent applications found in electronics and electrical engineering. In the consumer electronics realm, it is indispensable for attaching components to printed circuit boards (PCBs) in devices such as smartphones, laptops, and televisions. The automotive industry also heavily depends on solder wire to create reliable electrical connections in systems like sensors, infotainment units, and electronic control modules. In telecommunications, solder wire is crucial for ensuring consistent signal integrity within communication equipment and network infrastructure. Additionally, industrial environments utilize solder wire to assemble and maintain control systems and machinery, ensuring operational stability and durability. These varied applications underscore the indispensable nature of solder wire and emphasize the ongoing need for innovation to further enhance its performance and reliability across diverse technical fields.

Best practices for storing Solder Wire

Proper storage and handling of solder wire are crucial to maintaining its durability and ensuring consistent performance. To protect the wire from oxidation—particularly in humid environments—it should be stored in a cool, dry, and well-controlled setting. Routine inspections are advisable to detect any signs of surface contamination, corrosion, or thermal damage, all of which can compromise soldering effectiveness.

Prior to use, gently cleaning the solder wire with an appropriate solvent helps eliminate dust or residual debris, which may otherwise interfere with solder flow and joint integrity. Additionally, adopting a “first-in, first-out” (FIFO) approach in inventory management ensures older stock is used first, reducing the chance of performance decline due to prolonged storage.

By following these best practices for storage and upkeep, users can significantly extend the operational lifespan of their solder wire while preserving its reliability and quality over time.

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon